Ch 3: Morris Chang entering the semiconductor industry at Sylvania (2/3)

An English Translation of Morris Chang's Autobiography Vol 1 Ch 3 (Part 2) originally published in 1998

Note: This is an unofficial, non-commercial translation of Morris Chang’s memoir, shared for educational and entertainment purposes only. Full disclaimer below.

Improving soldering techniques

Sylvania hired me to utilize my mechanical expertise to automate their production line. Immediately upon joining, I was assigned to the germanium transistor production line. Both germanium and silicon serve as raw materials for transistors, but germanium, requiring lower processing temperatures, was used first. In 1955, except for Texas Instruments, which had already begun mass-producing silicon transistors, everyone else was still producing germanium transistors. Texas Instruments’ brilliant strategy to “leverage its small size and nimbleness to go after a big problem” led to their pioneering development of the silicon transistor in 1954. Other companies were still in the experimental stage with silicon transistors, and Sylvania lagged even further behind, only beginning to experiment with silicon transistors a year after I joined the company.

On the production line I was assigned to, there were about ten operators and one foreman; I was the sole engineer. About half of the operators performed a soldering step, attaching a fine copper wire to one of the transistor’s electrodes. Under a magnifying glass, the operator would thread the copper wire into the electrode (the electrode was a very soft metal), then touch the electrode with a high-temperature soldering tip to partially melt it and complete the soldering. Each transistor had two electrodes to solder, and a skilled operator could solder a few dozen transistors per hour.

Observing this soldering procedure for a few days, I noticed flaws. The soldering tip was very hot, and operators varied in skill. Some new operators kept the soldering tip in contact with the electrode for quite a while to complete the soldering, and the high temperature of the soldering tip could potentially affect the transistor’s internal chemical structure.

I took out my MIT textbook on Heat Conduction and did some rough estimates that confirmed my suspicion. Over the next few days, I experimented with an indirect heating method: instead of letting the soldering tip directly touch the electrode, it would only touch the copper wire. The high thermal conductivity of the copper wire could partially melt the electrode and complete the soldering.

My method was slower than the original but reduced the chance of disturbing the transistor’s internal chemistry, resulting in a higher final yield. After I mastered my technique, I trained two of the most experienced operators. Within a day or two, their speed using the new method reached 80–90% of the original approach.

We soldered a few hundred transistors using my new method and compared yields with another batch using the original. As expected, the new method produced better yields. My supervisor and the production manager came to see, and even the production manager sat down to learn my new soldering approach. A few days later, the entire production line switched to my method.

Though a small success with limited impact on the company’s bottom line, it was tremendous encouragement to me as a newcomer. The world outside school was not all thorns.

Self-studying semiconductors and beginning to show promise

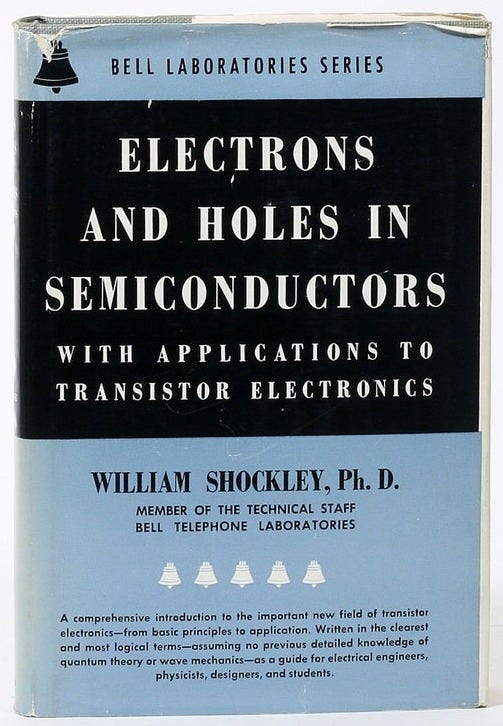

At the same time, I began self-studying semiconductors. My first textbook was Electrons and Holes in Semiconductors with Applications to Transistor Electronics by Shockley (one of the transistor’s inventors and a Nobel laureate). For a beginner, this was a formidable text. It reminded me of how I felt reading Homer’s ancient poetry six years earlier. Fortunately, my physics foundation was strong, and at least six years of undergraduate and master's training had taught me that when learning something, I needed to understand it thoroughly. I read word by word, sentence by sentence, paragraph by paragraph—reading, pondering, rereading, and pondering again. Sometimes I could manage only two pages in an entire evening; even in relatively straightforward sections, I might read only a dozen pages. Only after two months did I grasp the book’s most crucial parts.

Of course, self-studying was insufficient. Some passages baffled me no matter how much I reread and pondered. I had to ask someone. Who could I ask? At that time, I worked in Ipswich, a small town about 60–70 miles from Boston. A three-hour round trip made living in Boston inconvenient, but my wife still worked in Boston, so we hadn’t rushed to find a place in Ipswich. For the first two months, I stayed in the town’s only hotel. A colleague also living there, reputed as a semiconductor expert within Sylvania, became my first semiconductor teacher. The hotel room was uncomfortable, but the dining room was decent. My “teacher” was a heavy drinker who spent every evening from 6:30 pm until closing (around 10 pm) nursing drinks. He would order a dish occasionally, just to maintain the pretense of dining. I wasn’t much of a drinker then. I would join him for dinner—me eating, him drinking—and pose my questions. He was patient and answered willingly. Though he drank heavily, I never saw him truly drunk. He was genuinely knowledgeable. Most of my queries he could resolve. After dinner, I returned to my room to study. Sometimes a new question arose, and I would hurry back to the dining room before closing. He was always there, sipping alone.

When I joined Sylvania's semiconductor laboratory, they were already mass-producing transistors and expanding rapidly. A few months later, the company announced several major changes: the lab was renamed the “Semiconductor Division,” signifying it was now official business, not a laboratory curiosity. To strengthen the division’s management, headquarters dispatched a host of new managers to oversee us. Unfortunately, these newcomers all hailed from television or vacuum tube departments, nearly all ignorant of semiconductors.

True, at that time, semiconductor expertise was generally rare. But Sylvania could have transferred younger managers, with a strong technological background. Instead, the new managers were all middle-aged or older, with weak technical foundations. Also, the Ipswich site was too small, so the division moved to a new facility in Woburn, near Boston. Most employees welcomed the relocation, preferring to live closer to Boston. Having just rented a new apartment in Ipswich after two months in the hotel, I happily found another apartment near Harvard Square, returning to the Boston area.

The director who hired me originally had taken a better position elsewhere and left the company. After he left, few people mentioned automating the production line. In fact, it was at least a decade too early to discuss semiconductor automation, since processes constantly evolved, as evidenced by how I changed the soldering method within a few weeks. With processes constantly evolving, how could one automate?

I no longer worried that the original reason for hiring me had vanished. Over these months, my confidence in my semiconductor skills had grown daily. By now, I felt I knew more than most engineers in the production engineering department. My manager, the production engineering manager, valued me, and I began to attract the attention of other department heads.

Texas Instrument’s innovations and breakthroughs

Shortly after moving to Woburn, I was transferred to the R&D department—a promotion of sorts, since R&D personnel generally had higher degrees and technical standards than production engineering. I was appointed “section head,” though temporarily I was the only person, my superior assured me we had a budget for four engineers plus support staff. My section’s task was to develop new germanium transistors.

At that time, product and technical competition among semiconductor companies was already fierce. The main product was the “alloy” germanium transistor. Everyone strove to develop high-power or high-frequency germanium transistors. Some companies had advanced “diffusion” technology, enabling even higher power or frequency than alloy technology. (Note: Alloy and diffusion are two distinct transistor fabrication methods; alloy is cruder, diffusion more refined. After diffusion emerged, alloy gradually became obsolete.)

Meanwhile, silicon transistors had appeared a year before I joined the workforce. The birth of the silicon transistor was a fascinating story. Scientists knew from 1948 that silicon was a superior raw material for transistors, but its refining required very high temperatures and purity levels beyond then-current capabilities, so germanium was used first. Big companies had silicon research projects but expected it to take years.

Texas Instruments, a then-tiny company, got its transistor license from Bell Labs (and received some industry ridicule). But Patrick Haggerty, TI’s President, was ambitious and strategic. Soon after licensing, he poached Gordon Teal from Bell Labs. Teal was a key contributor to the transistor invention team. His departure from Bell to a small Texas company left the industry astonished. Bell Labs was the world’s most renowned research institution; TI a negligible newcomer. Texas conjured images of cowboys and oil, hardly culture or advanced technology.

At TI, Teal focused on silicon R&D. In May 1954, at a semiconductor academic conference, Teal presented a paper on “Some Recent Developments in Silicon and Germanium Materials and Devices.”1

Such conferences did not require pre-submitted manuscripts, so no one knew what Teal would say. Several presentations before him discussed silicon’s potential. One speaker, a research head from a major company, confidently stated that while silicon was progressing, it would take two or three more years to produce a practical silicon transistor. After he finished, Teal took the podium. Teal calmly described some experimental results, but there were still quite a few people in the audience half-asleep. Then, concluding his talk, Teal slowly said in his Texan drawl, “We have successfully fabricated silicon transistors whose performance matches experimental predictions. TI is in pilot production and expects to mass produce within a few months.”

Instantly, the dozing audience awakened, the hall tensed. Even before Teal finished, dozens of hands shot up in disbelief: “Did you say you have silicon transistors in production?” Prepared for this, Teal opted for a live demonstration rather than lengthy explanations. He motioned to a colleague waiting backstage carrying a bucket of hot water and took out two pocket radios from his pocket, one equipped with germanium transistors and the other with silicon transistors. He turned both on, music playing. He dunked the germanium set into the hot water; silence replaced the music. Then he immersed the silicon radio; the music continued unabated. A powerful demonstration. The audience rose to give a thunderous ovation.

Those scheduled to speak after Teal suffered as the crowd dwindled. In the hallways, excited groups formed, fervently discussing Teal’s announcement. Lines formed at payphones. If you passed by, you’d hear them shouting inside: “They’ve got the silicon transistor down in Texas!”

Redrawing the semiconductor industry map

TI's breakthrough in silicon transistors immediately redrew the market map of the semiconductor industry. Previously unknown, TI soared to dominate the industry for over two decades. More profoundly, TI’s triumph set a precedent for countless small tech companies: challenging giants was possible. David had a chance against Goliath!

Before TI, examples of small companies beating large ones existed, but usually after long struggles and mostly because big companies made major blunders, giving small companies a chance. In TI's case, the large competitors did not make serious mistakes, but TI surpassed them in just a few years. Why was this? Fundamentally, the pace of technological progress had clearly accelerated after World War II, and “technological turning points” emerged one after another. At each such point, large companies enjoyed no inherent advantage over small ones; both had almost equal opportunities.

Over the decades, innumerable instances of small surpassing large have emerged. In the past ten-plus years, Microsoft beating IBM is the most famous example. As far as I know, TI established the earliest paradigm.

At the end of 1955, when I was promoted to section head in the R&D department, a year after the silicon transistor’s debut, TI nearly monopolized that market. Still, germanium’s cost was lower, and most transistor sales remained in germanium. My responsibility was to develop various germanium transistors with different frequencies and power levels.

In over half a year, I hired four engineers—two bachelor’s and two master’s degree holders. Among the four, only one had some experience in the electronics industry; the other three were recent graduates fresh out of school. In addition, other support personnel such as technicians and operators were also hired within a year.

In 1956 and 1957, we developed nearly ten different germanium transistors. Besides supervising the four engineers, I also independently conducted research. At that time, an engineer could develop a transistor in a few months. Although all four were novices, and I alone had over six months’ experience, if the newcomers had a good foundation, after a few months of training, they could start R&D.

Our procedure was: design a transistor, run a trial production; if results were poor, redesign or retry; if good, produce a small batch and evaluate yield and quality.

If the product's performance, yield, and quality met or approached the predefined goals, we would report the results to our superior, and subsequent matters would be beyond our purview. We documented the design and manufacturing processes specifications. If upper management decided to mass-produce, the production department would manufacture according to these specifications. Occasionally, if mass production results are unsatisfactory, they would consult me or the engineers who developed the transistor. In such cases, we would go to the production line to help troubleshoot.

At Sylvania, I launched into a passionate, fervent, study of semiconductor technology. After mastering Shockley’s text in the first months, I relied mainly on contemporary academic papers and what I gleaned from daily R&D work. Fortunately, my new superior had a Harvard PhD and was well-versed in transistor theory, benefiting me greatly. From 1956 onwards, I attended semiconductor conferences two or three times a year. In December 1956, I published my first semiconductor paper and followed with two more in 1957. In retrospect, these papers were insignificant scientifically, but they elevated my standing inside and outside the company.

Disclaimer:

This is an unofficial translation of the memoir of Morris Chang. It is a non-commercial, unaffiliated work intended solely for educational and entertainment purposes.

All rights to the original text and its contents are fully retained by the original author and copyright holders. This translation has not been authorized, approved, or endorsed by Morris Chang, his representatives, or any affiliated publishers.

This content should not be relied upon for scholarly or commercial use, and no part of this translation may be reproduced, redistributed, or sold. If you are the copyright holder and have any concerns, please contact me directly.

Story recounted here: https://spectrum.ieee.org/the-lost-history-of-the-transistor